Key Points

- A pole barn is a post frame building that uses large wooden posts or laminated columns typically embedded in the ground or anchored to concrete piers to support the structure instead of relying on a continuous foundation.

- Originally developed in the 1930s using repurposed telephone poles, modern pole barns use engineered laminated columns and can span up to 100 feet without interior support walls.

- Pole barns cost 10-30% less than traditional stick built structures due to reduced materials, minimal foundation work and faster construction times.

- Common uses today include agricultural buildings, storage facilities, garages, workshops, horse arenas and even residential homes called “barndominiums.”

- While cost effective and versatile, pole barns require stable soil conditions and may face zoning restrictions or financing challenges in some areas.

Now that we’ve covered the basics, let’s go more in-depth.

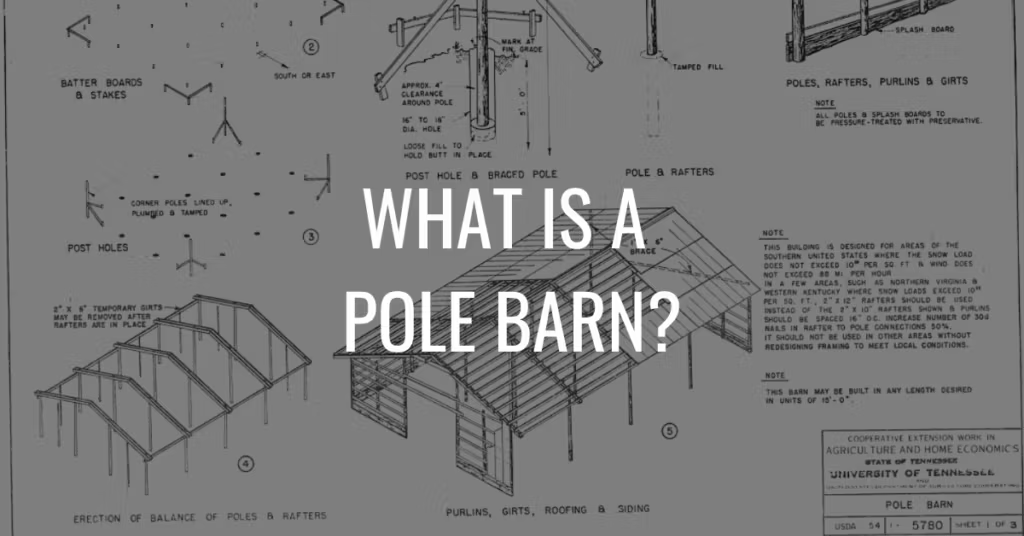

What is a Pole Barn?

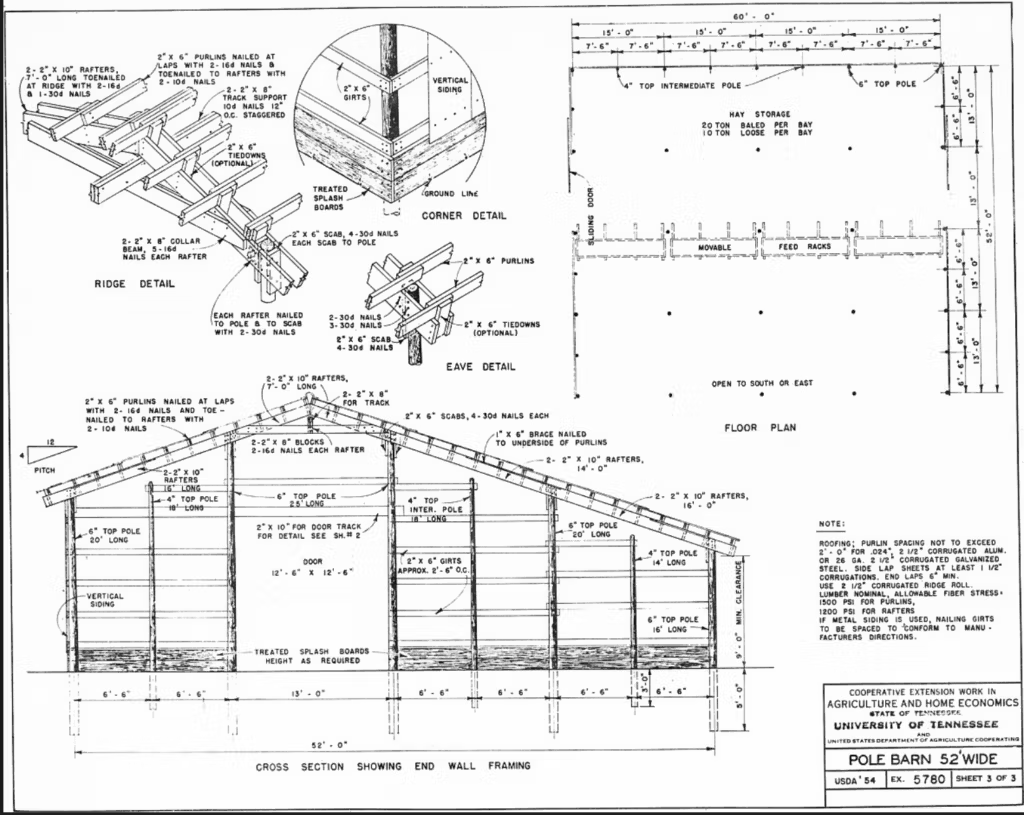

A pole barn is a simple building that uses large vertical posts as its main frame, eliminating the need for traditional continuous foundations. Most post frame buildings use pressure-treated laminated columns spaced 8-12 feet apart and embedded 4-6 feet into the ground with concrete footings for support.

The term “pole barn” comes from the historical use of old telephone poles as the main structural elements. But modern builders now call these structures post frame buildings, because we don’t use old telephone poles anymore. We use engineered laminated columns designed specifically for building construction.

Unlike traditional barn construction, a pole barn’s frame transfers all load directly through the posts into the ground, creating wide, column-free interior spaces. This design eliminates interior load bearing walls and allows for clear spans of up to 100 feet in advanced engineered designs.

How Post Frame Construction Works

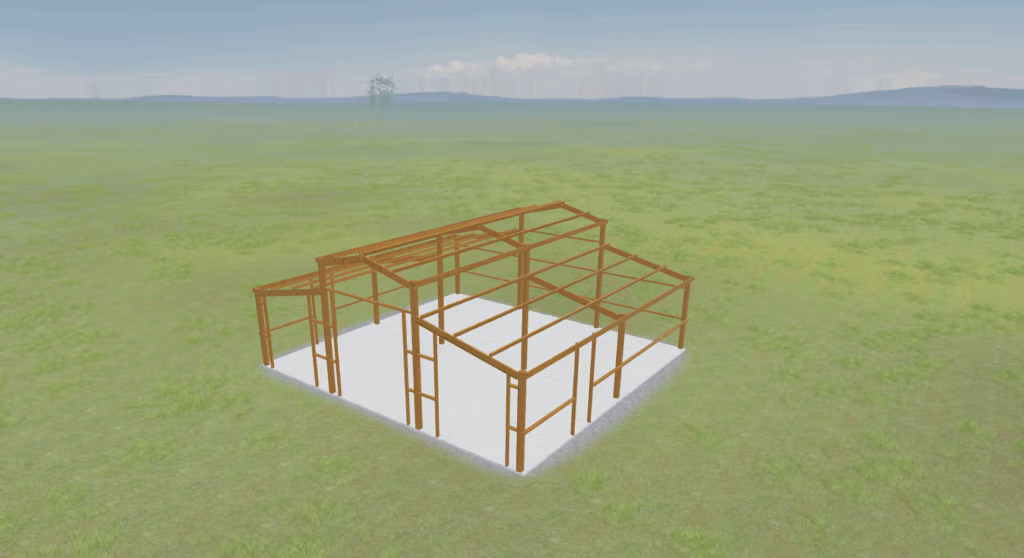

Post frame construction is a streamlined process that starts with minimal site work and excavation. Unlike traditional construction that requires a full concrete foundation, post frame construction only requires individual holes for each post (though a foundation may be used if desired), so construction time and labor cost is much lower.

The process starts with precise measurement and marking of post locations, typically 8-12 feet apart depending on the load requirements of the building. Each post hole is 4-6 feet deep, though depth varies based on local frost lines and soil conditions. The posts are then set plumb and secured with concrete footings.

Once the frame is up, roof trusses are installed between the posts. These engineered trusses can hold a lot of snow (depending on specific requirements) and provide the wide open spaces that make post buildings so versatile. The roof is completed with purlins that support the final roofing material.

Components of a Post Frame Building

The main structural components of post frame buildings work together to make a strong and efficient building system:

Laminated Columns or Posts: Modern post frame construction uses engineered, pressure-treated laminated columns instead of traditional round poles. These provide more strength, dimensional stability and weather resistance while carrying the entire building load.

Roof Trusses: Pre-engineered roof trusses span between the posts, no interior support structures are needed. These trusses are designed for specific snow loads and wind conditions based on local building codes.Steel Siding and Roofing: Metal roofing and steel siding is weather tight, durable and low maintenance. Steel materials also contribute to energy efficiency when insulated properly and can last decades with minimal upkeep.

Girts and Framing: Horizontal girts connect the posts and provide attachment points for wall sheathing. This framing transfers wind loads efficiently through the structure while keeping the building intact.

Concrete Footings: Pole barns don’t require a full concrete foundation, but each post is secured with concrete to prevent settling over time.

Modern Uses and Applications

Today’s post frame buildings serve far beyond their agricultural origins, adapting to meet diverse needs across residential, commercial and industrial sectors. The versatility of post frame construction makes it suitable for virtually any single-story application requiring large, open spaces.

Agricultural Buildings remain the most common application for pole barn construction. Farmers use these structures for livestock housing, equipment storage, hay storage and grain facilities. The wide open interiors accommodate modern farm machinery, while the cost effective construction allows farmers to build multiple structures as their operations grow.

Residential Applications have expanded significantly, with homeowners choosing pole barns for garages, workshops and hobby spaces. The growing trend of “barndominiums” combines residential living space with open barn areas, creating unique homes that offer both comfort and functionality for those with specific needs.

Commercial and Industrial Uses include warehouses, manufacturing facilities, retail spaces and office buildings. The ability to create large, column-free interior spaces makes post frame buildings ideal for businesses requiring flexible layouts and future expansion capabilities.

Equestrian Facilities represent a strong market segment, with horse arenas, stables and indoor riding facilities taking advantage of the clear-span capabilities. These buildings provide perfect space for training and housing horses while protecting both animals and equipment from weather.

Community and Recreational Buildings such as churches, community centers and event venues benefit from the open interior design and cost savings. The flexibility of post frame construction allows these organizations to create functional spaces within budget constraints.

Advantages of Post Frame Construction

Post frame construction offers many advantages that make it an attractive option for various building projects. Understanding these benefits helps explain why pole buildings have gained popularity across multiple sectors.

Cost Effectiveness is the primary advantage, with post frame construction typically costing 10-30% less than traditional stick built construction. This savings comes from reduced foundation work, less material usage and faster construction times that lower labor costs.

Faster Build Time is a result of the simplified building process and prefabricated components. Most post frame buildings can be built in days or weeks not months so you can use your new building sooner and reduce financing costs.

Minimal Foundation Requirements means no extensive excavation and concrete work. This saves material costs and site preparation time and makes pole barns possible on sites where traditional foundations would be a problem.

Large Open Interior Spaces without interior support columns gives maximum flexibility for current and future uses. Clear spans of 60-100 feet means efficient space utilization and easy reconfiguring as needs change.

Design Flexibility accommodates various architectural styles and functional requirements. Whether you want a utilitarian storage building or an attractive residential structure post frame construction can adapt to your needs and style.

Better Insulation Potential can be achieved with advanced framing techniques that reduce thermal bridging. With proper design, pole buildings can be as energy efficient as or more energy efficient than traditional construction.

Drawbacks

While pole barn construction has many advantages there are some drawbacks and limitations to be aware of.

Soil Requirements can limit where pole buildings can be built. Stable soil is essential for proper post installation and areas with extremely sandy, rocky or unstable soil may require additional engineering or alternative foundation methods.

Design Limitations become apparent for complex architectural features or multi-story construction. While post frame buildings are great for simple functional designs they may not be suitable for projects that require intricate architectural details or multiple levels.

Height Restrictions apply to buildings over 20 feet tall where engineering becomes more complex and costs increase. Most residential and light commercial applications stay within height limits but large industrial projects may require traditional construction methods.

Zoning Restrictions in some residential areas prohibit or limit pole barn construction. Local building codes and homeowners’ association rules may restrict post frame buildings especially for residential applications.

Financing Challenges can arise with some lenders who are not familiar with post frame construction. Traditional lenders may require additional documentation or engineering reports which can complicate the financing process.

Appraisal Issues can affect resale value as some appraisers are not familiar with post frame buildings. This can impact property values and make it harder to sell or refinance. Understanding the costs of pole barn construction helps you make informed decisions on your next project. Costs vary greatly depending on size, materials, location and use.

Cost Range for a basic pole barn is $15-40 per square foot for the building itself. This is for a simple building with basic finishes but doesn’t include electrical, plumbing or interior improvements that may be required for your application.

Factors that Affect Total Cost include building size, foundation requirements, roofing materials, siding choices, insulation levels and local labor rates. Adding features like overhead doors, windows, electrical systems or specialized flooring increases the overall cost.

Comparison to Traditional Construction shows pole barns are 10-30% less expensive than stick built structures of the same size. This is due to using less material, simpler foundation work and reduced construction time that lowers labor costs.

DIY vs Professional Installation is a big cost difference. Experienced builders can build a pole barn as a DIY project and save 20-40% on labor costs. But this requires the right tools, skills and knowledge of local building codes.

Long-term Maintenance and Operational Costs often favor pole barn construction due to durable materials like steel roofing and siding that require minimal maintenance. Lower heating and cooling costs can result from efficient design and proper insulation installation.

Pole Barn vs. Traditional Construction

Comparing post frame construction to traditional stick built methods highlights the key differences that affect your project decisions.

| Factor | Pole Barn Construction | Traditional Construction |

| Foundation | Posts with concrete footings | Full concrete slab or basement |

| Materials | Less wood and concrete | More framing lumber required |

| Construction Time | Days to weeks | Weeks to months |

| Interior Supports | None required for spans up to 100 feet | Load bearing walls needed |

| Cost | 10-30% less expensive | Higher upfront investment |

| Design Flexibility | High for single-story, open designs | Better for complex, multi-story |

Structural Differences between the two methods affect everything from site preparation to final appearance. Post frame construction transfers loads directly through posts to the ground while traditional framing distributes loads through walls to a continuous foundation.

Foundation Requirements is one of the biggest differences. Traditional construction requires extensive excavation and concrete work while pole barns need only individual post holes with concrete footings.

Construction Time and Labor favors pole barn construction for most single-story applications. The simplified process requires fewer specialized trades and can often be completed by smaller crews in less time.

Material Usage and Waste considerations show post frame construction uses fewer materials overall. The efficient design eliminates much of the lumber required for traditional wall framing while providing equivalent or better structural performance.

Interior Space Flexibility strongly favors pole barn construction for applications that require large open areas. Traditional construction requires interior support columns or complex beam systems to achieve similar clear spans.

History of Pole Barns

The concept of pole barns goes back to the great depression in the 1930s when American farmers were faced with material shortages and economic hardship. During that era, resourceful farmers began using surplus utility poles from telephone and power lines to build inexpensive storage buildings for farm animals and equipment. These early telephone pole barns required 60% less material than traditional stud wall construction, so it was the perfect solution during the great depression when building costs had to be minimal. The economic situation made this a necessity rather than a choice and it took off as families needed affordable shelter and storage.

World War II accelerated the use of post frame construction due to government imposed material rationing and building cost limits. The efficiency of using less material and building functional structures fit perfectly with the national need for frugality and resource conservation.

The post war period eventually closed the gap between pole barn construction and conventional building methods. As farming operations modernized and needed bigger machinery storage, the demand for wide open barns grew. This shift towards fast construction and open interior spaces solidified pole barn construction as the preferred method for farm buildings.

By the 1960s and 1970s the construction industry began to recognize the versatility of post frame buildings beyond farm use. Builders started to adapt the technique for commercial, residential and industrial projects and today we have the diverse applications and the term “post frame construction” to use.

For a more in-depth breakdown of pole barn history, read our post here.

Frequently Asked Questions

How long do pole barns last with proper maintenance?

Modern post frame buildings built with pressure-treated laminated columns and quality materials last 40-60+ years with proper maintenance. The key factors are soil drainage around posts, quality of pressure treatment and regular maintenance of roofing and siding systems. Steel roofing and siding can extend the building’s life significantly compared to other materials.

Can pole barns be built on uneven or sloped terrain?

Yes, pole barn construction adapts well to uneven or sloped sites because each post can be set at different depths to accommodate grade changes. This flexibility eliminates the need for extensive site grading or complex foundation systems required by traditional construction. However, extreme slopes may require additional engineering and could affect the overall project cost.

What permits and inspections are required for pole barn construction?

Permit requirements vary by location but most areas require building permits for structures over a certain size (typically 200-600 square feet). Where we build in Utah and Idaho, there are also agricultural exemptions available in some cases. Common inspections include footing/foundation inspection before concrete is poured, framing inspection and final inspection. Some jurisdictions may also require electrical and plumbing inspections if these systems are included. Always check with local building departments before starting any project.

Are pole barns suitable for year-round use in cold climates?

Yes. With proper insulation and air sealing, post frame buildings perform well in cold climates. The key is designing the thermal envelope correctly and eliminating thermal bridging through proper construction techniques. Many pole barns in northern climates achieve energy efficiency levels comparable to traditional construction when properly insulated.

Can existing pole barns be expanded or modified after construction?

Pole barns are very adaptable. Existing buildings can be added to by adding bays, and interior modifications are easy since there are no load bearing walls to worry about. But any structural changes should be engineered by a professional to make sure they don’t compromise the building or violate local codes.

P.S. If you’re looking to build a quality pole barn or barndominium in Northern Utah or Southern Idaho, get in touch.